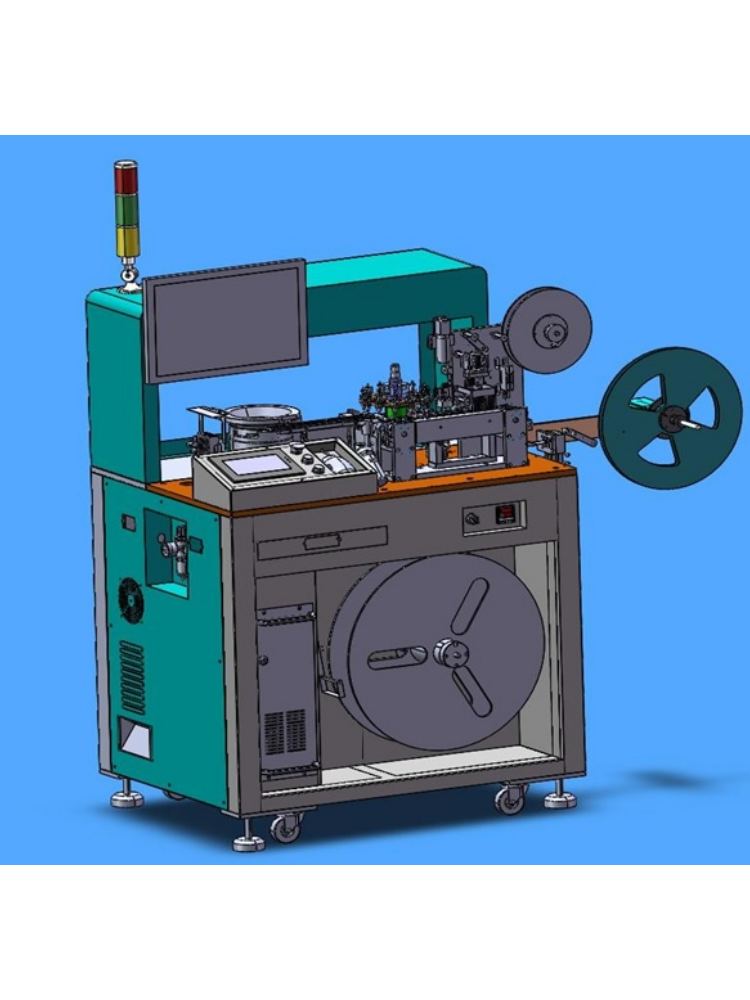

Automatic SMD Tape and Reel Machine with Rotary Tower Assembly HJC-020S

Name: High Speed SMD Component Taping Machine with Rotary Tower

Model: HJC-020S component testing and sorting

Application:Be used for the electrical performance test,appearance inspection and tape and reel packaging of inductor/IC products.

high speed tape and reel machine|semiconductor tape and reel|semiconductor packaging|IC testing and sorting|IC handler|semiconductor testing and sorting|IC tester|wafer testing and sorting|die testing and sorting|automated IC testing and sorting|IC testing and sorting machine|

Features:

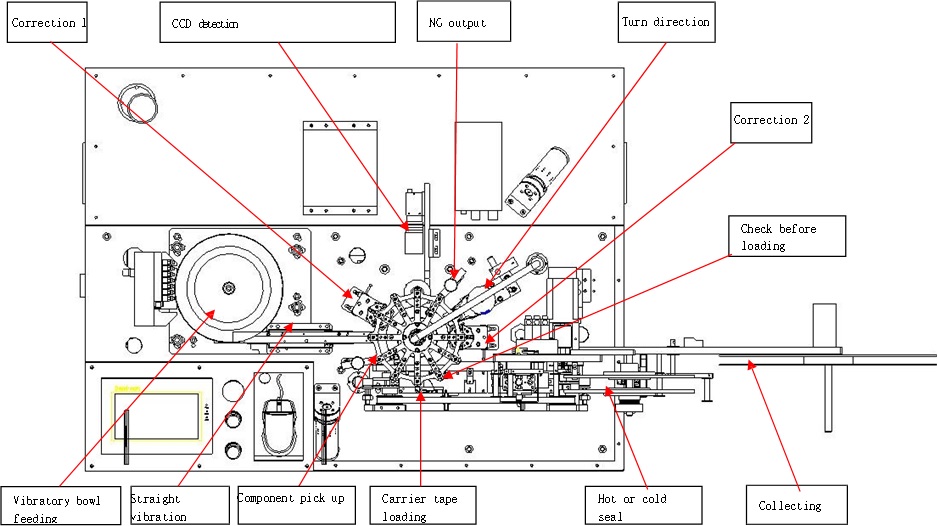

1. Vibratory bowl feeding (one component size, one feeder);

2. 12 stations of rotary tower design, with correction, defective removal, collection function(one component size, one set of rotary tower)

3. Before sealing, CCD inspection station can check direction/ character/ polarity etc.(customized solution)

4. Hot-sealed self-adhesive upper cover tape sharing different sizes, carrier tape reel sharing different sizes;

Function introduction:

Introduction: This equipment is a tape and reel device for bulk semiconductors. The process is to feed bulk component by vibration bowl, pick component by vacuum manipulator to the carrier tape. This machine can handle components with cavity depth≦5mm and width ≦24mm.

|

Item |

Parameters |

|

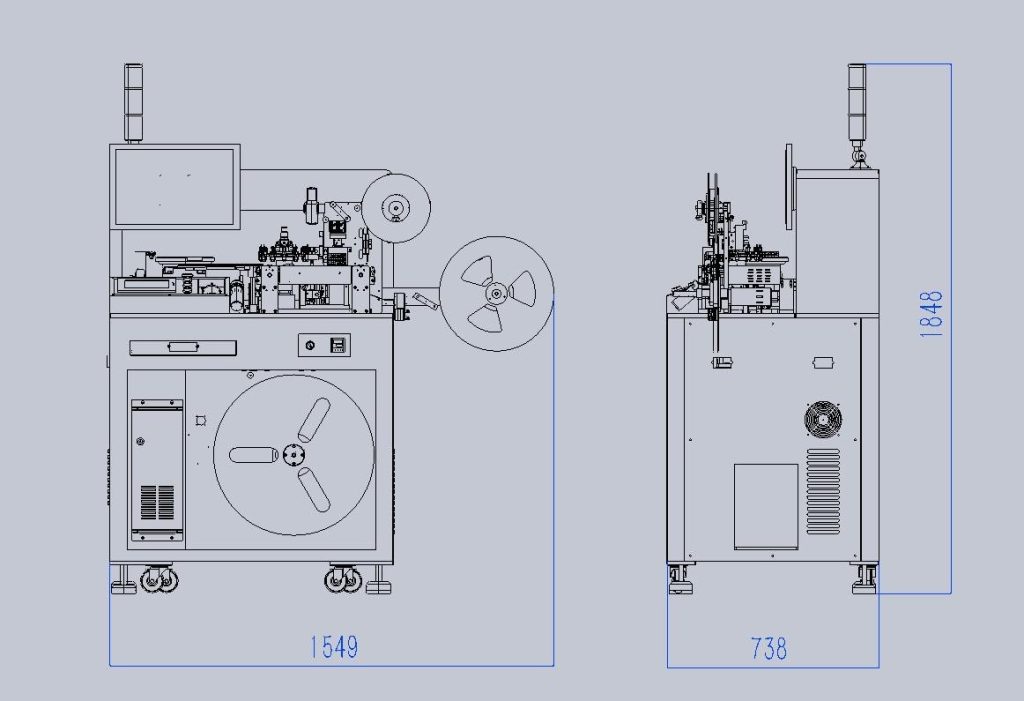

Dimension |

L*W*H: 1500mm * 740mm * 1600mm |

|

Weight |

200kg |

|

Power system |

Single-phase AC220V,50HZ, |

|

Air source |

5.0kg/cm2≦ air pressure ≦9.0kg/cm2 |

|

Rated power |

4.6KW |

|

Feeding system |

Carrier wheels and supporting upper covers for EIA-481A standards |

|

Tape specifications |

Width ≦24mm depth ≦5mm |

|

Temperature control system |

Single-head adjustable PID thermostat with temperature control at 120℃ to 200℃ |

|

Speed |

5000-15000pcs/h, decided by component specifications |

|

Counting function |

The internal pulse count of the system |

|

Sealing |

Self-adhesive / hot pressure |

|

Reel spec |

13 inch,15 inch,22 inch,27 inch plastic reel or paper reel |

|

The working environment |

Dust-free workroom,0℃≦ temperature ≦50, 35%≦humidity ≦85% no condensation |

Options:

- Rotary tower stations can be 12 or less;

- 2D camera can check component from upside and downside;